Ultrasonic inspection is a nondestructive method in which high frequency sound waves are introduced into the material being inspected.

Ultrasonic testing uses high-frequency sound waves called ultrasonic pulse waves to detect flaws or other imperfections or defects in metal components, and it can also be used to identify and monitor changes like shifts in thickness within the components that may result in failure or other problems in the future.

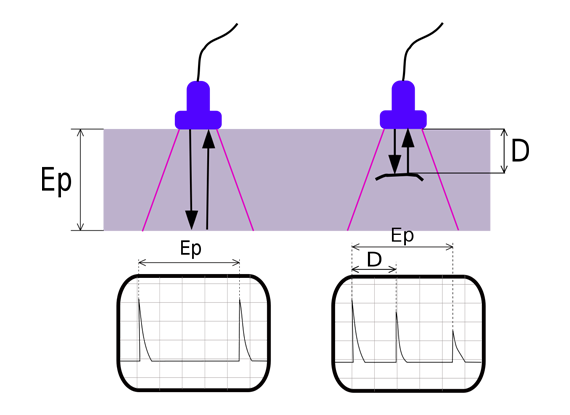

Ultrasonic weld inspections are typically performed using a straight beam transducer in conjunction with an angle beam transducer and wedge.

This ultrasonic inspection may include the root, sidewall, crown, and heat-affected zones of a weld. The process involves scanning the surface of the material around the weldment with the transducer.

The most commonly occurring defects in welded joints are porosity, slag inclusions, lack of side-wall fusion, and lack of inter-run fusion, lack of root penetration, undercutting, and longitudinal or transverse cracks

NDT Consultancy Services provides inspection in Ultrasonic Testing (UT): Ultrasonic Training.

Manual Shear wave Examination of weld ment and other complex geometry Manual Compression or Shear Wave Examination of Casting /Forging

- ASME Section V, Article 4, 2004 Edition

- ASME Section I, Boilers

- ASME Section VIII, Pressure Vessels

- ASME B31.1, Power Piping

- ASME B31.3, Petrochemical Piping

- AWS D1.1

- API 1104

- API 6AUltrasonic Training